บริษัท พีเอ็น เซอร์วิส วาล์ว จำกัด

PN SERVICE VALVES

|

บริษัทในเครือ PN SERVICE VALVES วาล์ว รับงานซ่อมบำรุงรักษา VALVE ในโรงงานนิคมอุตสาหกรรม งาน SHUTDOWN โรงไฟฟ้า , โรงกลั่น , โรงงานปิโตรเคมี , โรงน้ำตาล , โรงงานอาหาร ฯลฯ

|

INDUSTRIAL OVERHAUL ALL VALVE

TOOLS LIST

MANUAL VALVE CLEANING PROCEDURE

1. Inspect outside and clean body , bonnet , inlet and outlet by Instrument air.

2. Record Tag No. Mfg. data in check sheet.

3. Remove lock nut and hand wheel nut.

4. Remove hand wheel.

5. Remove stem plug form the body valve.

6. Disassembly bonnet and valve.

7. Remove stud bolt between bonnet and valve body.

8. Cleaned body , stem plug , inside ,outside hand wheel , gland flange.

9. After cleaning and component , then inspect plug and seat valve. If damage they were need it repair lapping. ( Refer to repair procedure )

10. Assembly all part and accessory.

11. Test leakage and shell test follow API 598.

SCOPE OF SERVICE

REMOVE / INSTALL VALVE DISMANTLE. PART INSPECTION. DISC , SEAT RECONDITION BY LAP. HYDROSTATIC SEAT TEST AND SHELL TEST. HARD FACE WELD REPAIR. ON SITE LAPPING.

STANDARD API 598 HYDROSTATIC SEAT AND SHELL TEST AS FLANGE CLASS RATING. LOW PRESSURE TEST ( BACK SEAT TEST ).

JOB : PTT TANK

5, I-1 Road, Map Ta Phut, Rayong, Rayong 21150

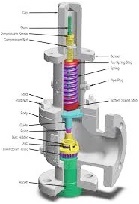

PROCEDURE SAFETY VALVE

SAFETY VALVE CLEANING PROCEDURE

1. Inspect outside and clean body, bonnet , inlet and outlet nozzle by Instrument air.

2. Record Tag No. Mfg. Data in check sheet.

3. Remove spindle nut.

4. Marking adjusting bolt lock nut , bonnet , valve body and record in check sheet.

5. Remove the adjusting bolt lock nut.

6. Remove stud bolts between bonnet and valve body.

7. Disassembly bonnet and valve body.

8. Marking guide ring and Nozzle ring.

9. Cleaned spindle springs , spring washer , nozzle , disc holder insert and guide.

10. After cleaning and component, then inspect nozzle and disc . If damage they were need to repair or lapping ( Refer to repair procedure)

11. Assembly all parts and accessory.

12. Test Lapping , setting and leak test . ( Refer to repair procedure )

SCOPE OF SERVICE PART INSPECTION DISC NOZZLE RECONDITION BY LAPPING OR MACHINE POPING AND SEAT TIGHTNESS TEST ON SITE HOT FLOW TEST AND ADJUSTMENT ON SITE MAINTENANCE FOR ( BW VALVE ) ALL TEST ARE PEREFORMED ACCORDING TO API 527 / ASME SECTION I – SECTION VIII POPING TEST & RE - ADJUST SEAT TIGHTNESS TEST BACK PRESSURE TEST ( FOR BELLOW VALVE ) |

|

JOB : GLOW ENERGY PUBLIC COMPANY LIMITED

PROCEDURE CONTROL VALVE

CONTROL VALVE CLEANING PROCEDURE

1. Inspect and clean outside with Instrument air .

2. Record Tag No, and Mfg. data in check sheet.

3. Marking bonnet and valve body.

4 . Disassembly bonnet and valve body.

5. Inspect plug and seat check damage part .

6. Cleaning all wet part .

7. If disc and plug to wear out it needs to repair as follow up repairing procedure.

8. Change damage part it necessary.

SCOPE OF SERVICE THIS STANDARD DETEILS THE TEST PROCEDURE AND ACCEPTANCE STANDARDS FOR SEAT EAKAGE IN CONTROL VALVE AS DEFINED BY ANSI B16.104 ( FCI 70-2 ) CONTROL VALVE SEAT LEAKEGE ANSI LEAKAGE CLASSES USED IN THIS SPECIFICATION CLASS I - SEE PARAGRAPH. CLASS II - 0.5% OF RATED VALVE CAPACITY. CLASS III - 0.1% OF RATED VALVE CAPACITY. CLASS IV - 0.01% OF RATED VALVE CAPACITY. CLASS V - 5 X 10 - 4 ML PEP MIN. OF WATER PER INCH OF SEAT DIAMETER PER PSI DIFFERENTIAL. CLASS VI - SEE PARAGRAPH. |

|

JOB : Myanmar Lighting IPP Co ., Ltd

PROCEDURE ON - OFF VALVE

ON - OFF VALVE CLEANING PROCEDURE

1. Inspect outside and clean body , bonnet , inlet and outlet by Instrument air.

2. Record Tag No. Mfg. data in check sheet.

3. Remove lock nut and hard wheel nut.

4. Remove hard wheel.

5. Remove stem plug form the body valve.

6. Disassembly bonnet and valve.

7. Remove stud bolt between bonnet and valve body.

8. Cleaned body , stem plug , inside ,outside hand wheel , gland flange.

9. After cleaning and component , then inspect plug and seat valve. If damage they were need it repair lapping. ( Refer to repair procedure )

10. Assembly all part and accessory.

11. Test leakage and shell test follow API 598.

SCOPE OF SERVICE REMOVE / INSTALL. VALVE DISMANTLE. PART INSPECTION. DISC , SEAT RECONDITION BY LAP. HYDROSTATIC SEAT TEST AND SHELL TEST. HARD FACE WELD REPAIR. ON SITE LAPPING. STANDARD API 598 HYDROSTATIC SEAT AND SHELL TEST AS FLANGE CLASS RATING. LOW PRESSURE TEST ( BACK SEAT TEST ). |

|

JOB : HMC Polymers Co., Ltd

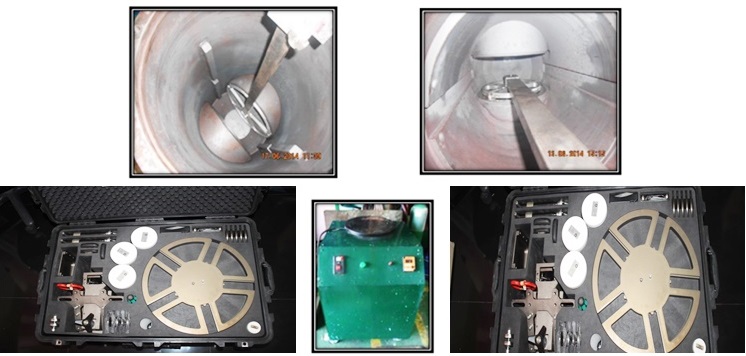

TESTING & LATHE TOOLS

LAPPING TOOLS

SOFT PART PRODUCT

ที่อยู่/แผนที่ 19/8 ซ.หัวน้ำตก 3 ถ.หัวน้ำตก ต.มาบตาพุด อ.เมืองระยอง จังหวัดระยอง21150

มือถือ : 081-1023154 , 065-2478952

Fax : 038 694072

E-mail: pnservicevalves@gmail.com